Industries

PUBLIC PARKS

A green revolution has taken place in the City in the form of development of Parks, Landscapes, Traffic Islands, etc. The city is with a unique harmonious blend of Tradition and Modernity with multi-storeyed buildings of Industrial/ Residential/ Commercial.

It has increasing trend of Global Warming and Pollution due to growing No. of industries and Vehicles.

This major development with emphasis on greenery reduces the carbon-dioxide content in the atmosphere and allows the citizens to breathe pollution free air in the vicinity of Parks. It Provides lung spaces for the city and enable children to play safely and serves as peaceful place for walking entertainments etc. it also adds aesthetics and thus transformation from a dry city to a green aesthetic city.

Currently, developed countries have tended to adopt a general standard of green space of 20 sqm park area per capita. The World Health Organization (WHO) recommends that cities should provide 9 sqm of undeveloped (unpaved) open space for every inhabitant. The WHO also suggests designing green area networks so that all residents live within a 15 minute walk to an open space.

The parks range in size from 700 square meters to 5,000 square meters. The per capita green cover of the city has been estimated at 8.5 square meters, as against the World Health Organization recommendation of 9 square meters of green cover per capita in cities.

The average amount of water required to maintain the parks in the city is 5 litres per square meter, ie for an average of 2000 Sqmeter of Parks, water requirement is (2000 x 5 = 10,000 Liters per day).

At present water is drawn through Bore well inside the park or Corporation water, Most of the places the Quality & Qty of Ground water is poor because of the contamination which needs treatment. Sufficient quantity of Municipal water is not available. Resulting The parks goes to dry condition due to the water shortage in summer season the water source gets depleted.

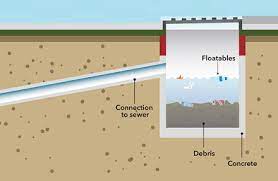

Hence SWARAJ suggest to draw sewage from the public sewer line, treat it and use for developing and rejuvenating the greenery of the city without the shortage of water by reusing the treated wastewater available nearby the parks and their vicinity.

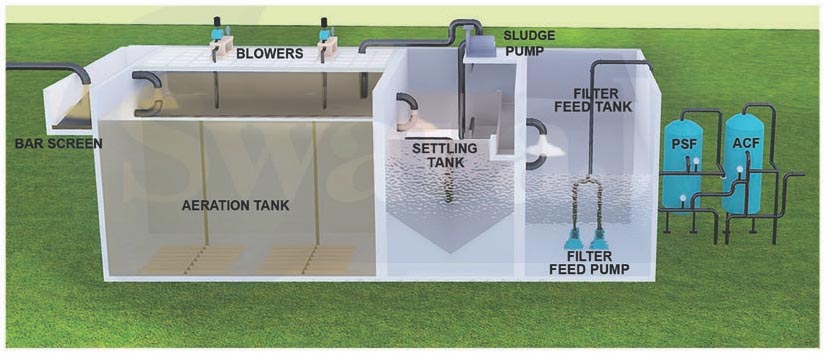

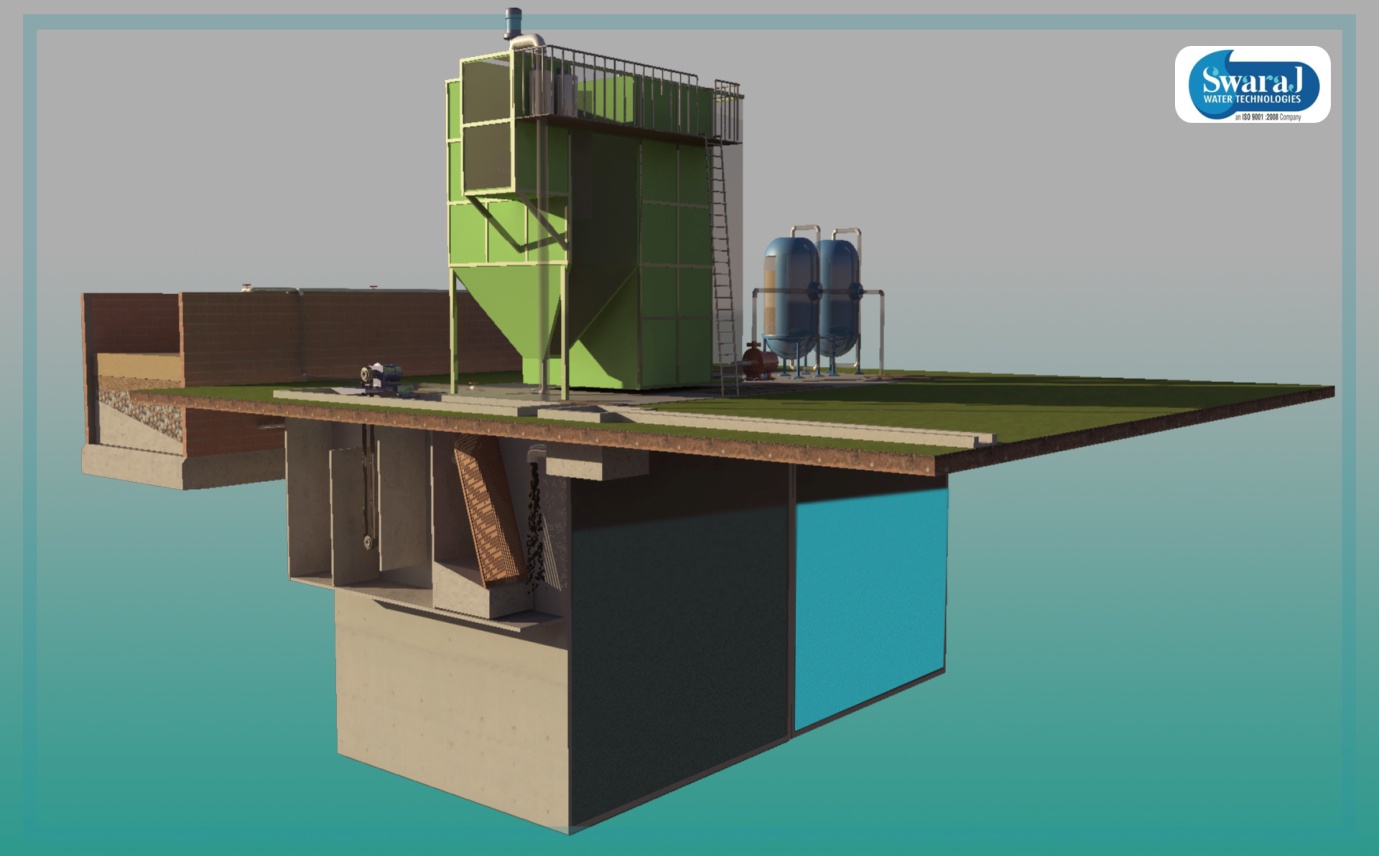

SWARAJ Modular Sewage treatment plants consisting of Biological treatment & Filtration.

EXPECTED TREATED CHARACTERISTICS

| Sl. No | Parameter | Expected Value | P CB Norms |

| 01 | Ph | 6.5 – 7.5 | 5.5 – 9.0 |

| 02 | Total Suspended Solids | < 10 mg/l | < 100 mg/l |

| 03 | Oil & Grease | NIL | < 5 mg/l |

| 04 | Chemical Oxygen Demand | < 100 mg/l | < 250 mg/l |

| 05 | Bio-Chemical Oxygen Demand | < 10 mg/l | < 20 mg/l |

SALIENT FEATURES OF THE PACKAGE SYSTEM

- All systems controlled by automation panel

- Level switches and float given for the operation of pumps as per the requirement of water in the park.

- Aeration tank operated continuously for 24 hrs

- No need of continuous monitoring and man power, have to monitor once in a day to check automatic filter valves & panel board.

- Since the Treated water has nutrients requirement of fertilizer is reduced.

- Being Modular can be executed fast & in case required can be transported

- Aesthetically good looking

Than letting out the sewerage into public drain these sewage to be treated and used back for Flushing, Floor washing, Gardening, etc there by more than 50% of freash intake of water can be reduced.

HOSPITALS

Hospital Waste is a highly hazardous waste. Wastewaters generated from hospitals contain pharmaceuticals residues, pathogens, chemical reagents, radionuclide, and other harmful matter.

These effluents also carry pathogenic microorganisms such as viruses, bacteria, fungi, protozoans, and helminths which induces pressure of rapid adaptation to these fluctuating conditions through genome rearrangement in innate microorganism.

“A Hospital is not a place to be sick”

Process Description

1. Primary Treatment

- i. Screen Chamber

- ii. De-gritting Chamber

- iii. Oil & Grease removal (Gravity & Mechanical belt skimmer)

- iv. Equalization Tank

2. Secondary Treatment

- i. Moving Bed Bio Reactor

- ii. Settling tank

3. Tertiary Treatment

- i. Sand Filter

- ii. Disinfection

- iii. Carbon Filter

4. Re Use

- i. Chemical Treatment

- ii. Ultra Filtration

EXPECTED TREATED SEWAGE CHARACTERISTICS

| Sl No | PARAMETERS | Expected @ ACF | Expected @ UF | PC Board Norms |

| 01 | Ph | 6.5 to 7.5 | 6.5 to 7.5 | 5.5 to 9.0 |

| 02 | Total Suspended Solids | <5 mg/l | <1 mg/l | < 10 mg/l |

| 03 | Oil & Grease | Nil | Nil | < 5 mg/l |

| 04 | Chemical Oxygen Demand | <50 mg/l | <10 mg/l | < 250 mg/l |

| 05 | Bio-Chemical Oxygen Demand | <10 mg/l | <3 mg/l | <20 mg/l |

SCHOOLS & COLLEGES

Most of the educational institution has large areas around , Developing Greenary around shall change the atmosphere, For to develop Greenary large qty of water required, Because of the shortage of water development of Greenary is less

Swaraj suggest to reuse the sewage generated for Gardening purpose which shall help in drawing more water from the ground, The percolation shall help in increasing the water table.

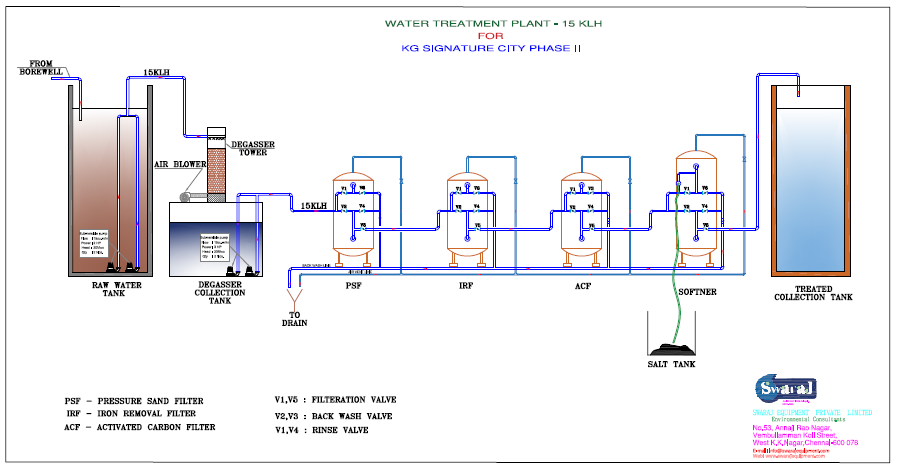

Since the waste water generated is mostly Sullage & Lots are Holidays are there we have suggested Chemical treatment followed by Filtration.

SALIENT FEATURES OF THE PACKAGE SYSTEM

- All systems controlled by automation panel

- Level switches and float given for the operation of pumps as per the requirement of water in the park.

- Plant operates only when Waste water is there in Collection Tank

- No need of continuous monitoring and man power, have to monitor once in a day to check automatic filter valves & panel board.

- Being Modular can be executed fast & in case required can be transported

- Aesthetically good looking

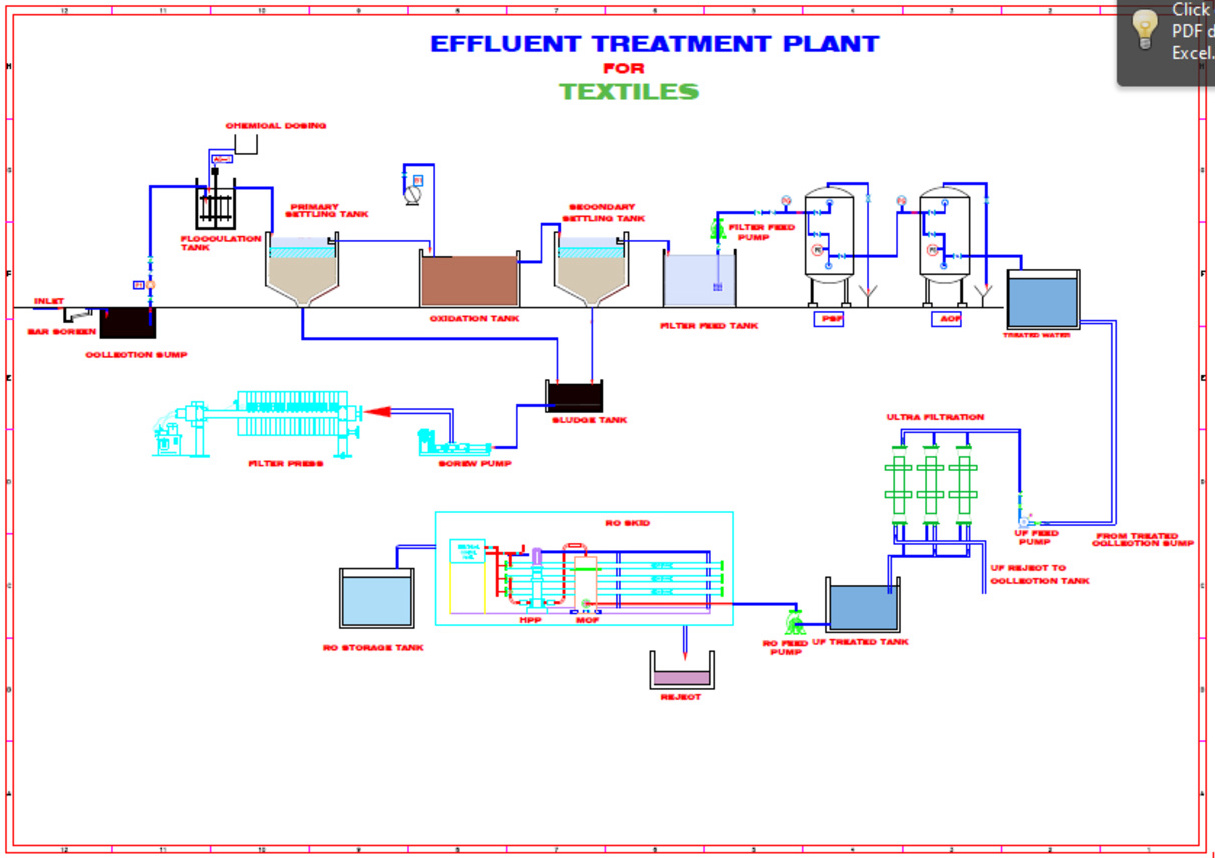

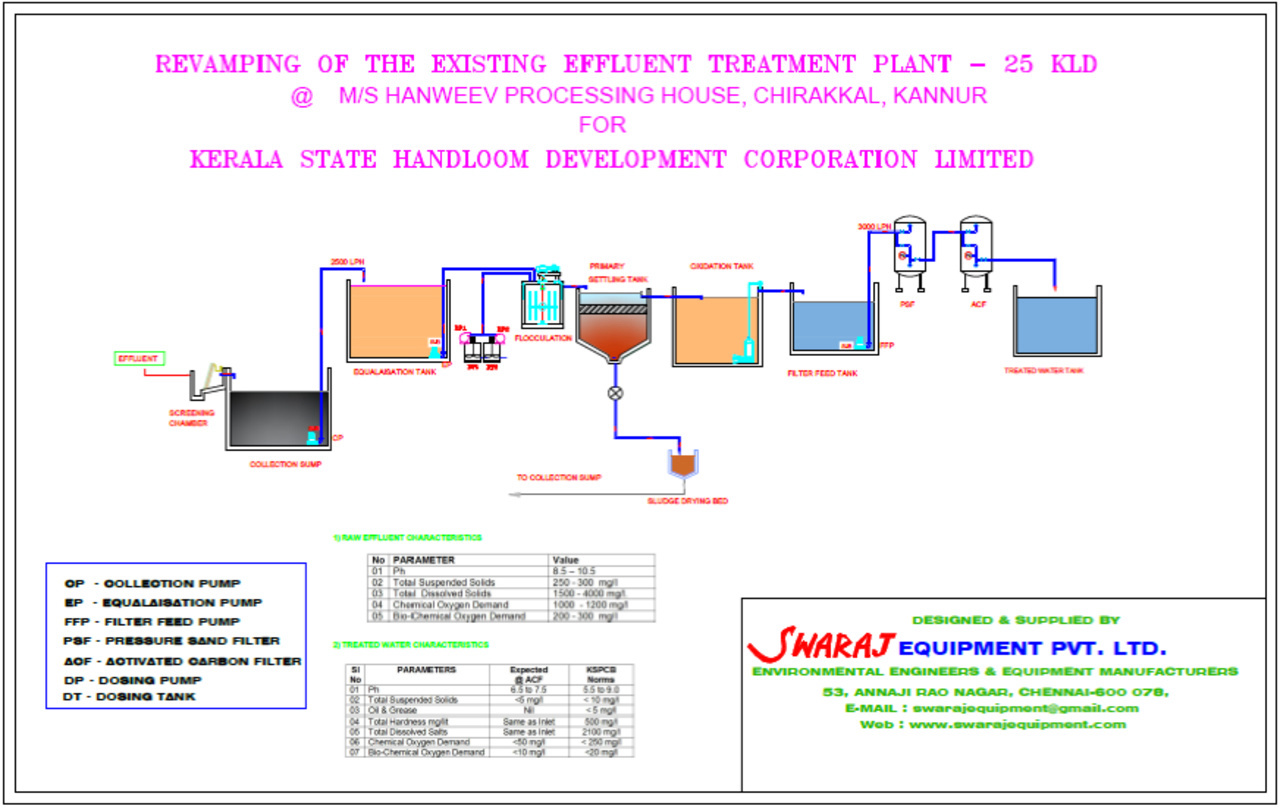

TEXTILE INDUSTRY

The Waste water generated after Dyeing & Processing are highly hazardous in nature Waste As per the pollution control board regulations Zero discharge Treatment plant to be installed & is Mandatory The treatment system consist of

Produced waste water shall be used back for the process allowing evaporation Losses.

1. Primary Treatment

- i. Screening

- ii. Degritting

- iii. Collection

- iv. Flocculation

- v. Primary Settling

2. Secondary Treatment

- i. Oxidation

- ii. Sec Settling

- iii. Collection

- iv. Flocculation

- v. Primary Settling

3. Tertiary Treatment

- i. Flash Mixer

- ii. Tertiary Settling

- iii. Pressure sand Filter

- iv. Activated Carbon Filter

4. Re Use

- i. Ultra Filtration

- ii. Reverse Osmosis ( Upto 3 Stages)

- iii. Multiple Effect Evaporater

- iv. Activated Carbon Filter

SAGO INDUSTRY

Processing of tapioca requires 20,000 to 30,000 L of water per tonne of sago. Since the Waste water generated is Acidic and has high BoD of 15,000 mg/lit , CoD of 25,000 mg/lit & TSS of 1,000 mg/lit , it produces foul-smelling and cannot be discharged into the land.

We SWARAJ developed a Technology for the treatment with a Combination of Anaerobic treatment (UASBR) followed by Aerobic (ASP) & Filtration (PSF & ACF).

From the Anaerobic treatment (UASBR) GAS is produced @ 1.0Cum / 3.5 Kg of CoD reduced & can be used for Heating application or Power generation after purifications.

The Treated effluent at the outlet of ACF shall be Neutral and shall have BoD < 20 mg/lit , CoD < 150 mg/lit & TSS < 10 mg/lit.

We have installed more than 250 Treatment plants ranging from 100 KLD to 2.0 MLD.

FOOD & BEVERAGE

With a wide range of companies in the food and beverage industry from juice manufacturers, dairy facilities, and meat packing plants, to breweries, wineries, and everything in-between, Whether you’re looking to de-bitter your product, improve taste, remove muddiness, or eliminate odour, we help to produce the finest goods and improve process and equipment efficiency with lowest cost, and our various technological advancement.

Enquiry Form

Please fill out the form below and allow 48 business hours for our reply. We look forward to responding to your query.