Solutions

Water reclamation/recycling predominantly makes non-potable wastewater useful, consequently saving the economic & environmental expenditures related to establishing new water supplies. It is the process of collecting, treating and using wastewater generated from municipalities, industry and agriculture. The recycled water can be used for domestic, irrigation or industrial purposes if properly treated. In specific cases, treated wastewater is indirectly used for drinking purposes, i-e by implanting it into groundwater aquifers to increase capacity and minimize salt water intrusion. It is an important adaptation response to climate change as the increasingly unpredictable weather patterns and their effects, for example as severe droughts and sea level rise, are likely to have negative consequences on freshwater resource quantity and quality.

Sewage Treatment Plant

The purpose is to remove the harmful substances so that it can be introduced into the environment without affecting public health or environmental issues. It is mandatory by the pollution control board that sewage should be treated before letting into the environment.

Treatment includes physical, biological and filtration methods, the plants are tailor made according to the area available and can be constructed below or above the ground.

Various methods

- Activated Sludge Process (ASP)

- Moving Bed Bio Reactor (MBBR)

- Sequencing Batch Reactor (SBR)

- Membrane Bio Reactor (MBR)

Modular STP’s

Ever wondered where all the solid waste materials in the sewage water like shampoo wrappers, rags, plastic bottles and materials and other coarse objects end up? Don’t worry, all the outliers in the sewage water are safely filtered in this preliminary stage and are sent away to the GHMC landfills.

Also called as sedimentation this stage further separates the solid waste from the liquid water of the sewage water. As all the organic and inorganic solids that dodged the preliminary stage settle down, the liquid waste is skimmed to the next stage with skimmers.

As the water is sent to aeration tanks where the aerators mix the oxygen with the water to help microorganisms break down the biodegradable materials present in the water. This stage focuses on the removal of suspended biological matter and other organic materials.

While all the biological materials, both solid and liquid are completely removed in the first above stages, the tertiary stage removes all the inorganic materials and pathogens using chemical and UV light treatments. The water released now can be used for all the non-potable uses like flushing, irrigation, washing cars, gardening or even construction, and removed sludge can be utilized as fertilizer for plants.

Modular STP’s

Packaged Sewage Treatment Plant is designed compact that is utilized in a decentralized manner at any location,

They are highly durable FRP/ MSEP tanks. A Package sewage treatment plant is a completely self – contained system for sewage treatment that is ‘plug & play’. Packaged STP is designed to bring the treated sewage parameters (BOD, COD, TSS, TN etc.) below the permissible limit which is stipulated by the Pollution Control Board.

Advantages:

- Compact & Fast Installation

- Tailor made to suit Site conditions

- Consists of Secondary & Tertiary Treatment Systems

- Biological followed by Filtration for Organic waste water

- Chemical followed by Filtration for In Organic waste water

- Easy to Clean & Low Maintenance

- Fully road transportable assembled

- Semi Automatic & Automatic depending on Customer requirements

SWARAJ Modular Treatment Plant are available from 500 to 200000 litres a day , Tailor made to suit the Customer requirements.

Effluent Treatment Plants

With the rising industrialization, Effluent treatment is crucial to dispose effluents without danger to the human health and overall environmental safety.

It is also mandated by the Pollution Control Board to install these plants and follow their stringent regulations up to Zero Discharge Plants depending on the characteristics of Raw effluent. Swaraj brings deep product expertise and extensive process knowledge.

We analyse the manufacturing process, So as to control the waste water produced at the Source there by implementing Economical Solutions.

We also identify the factors contributing to a plants design, including recycle requirements, land availability, energy, labour and disposal costs. We also provide expertise to improve the performance of the existing plant to the Stringent standards stipulated by the Pollution Control Boards:

We have executed ETP for the following industries:-

- Distilleries & Breweries

- Textile Dyeing Units

- Leather Processing

- Pharma

- Sago Industries

- Food industries

- Service Centres

- Slaughter house

Activated Sludge Process (Asp)

ASP is the biological process by which non-settleable substances occurring in dissolved and colloidal forms are converted into settleable sludge which is removed from the liquid using aeration and a biological floc composed of bacteria and protozoa.

Moving Bed Bio-Film Reactor

MBBR-Moving Bed Biofilm Reactor process utilizes floating plastic carriers (media) within the aeration tank to increase the amount of microorganisms available to treat the wastewater.

Sequential Batch Reactor (Sbr)

SBR-Sequencing Batch Reactor is a fill-and- draw activated sludge system for wastewater treatment. In this system, wastewater is added to a single “batch” reactor, treated to remove undesirable components, and then discharged.

Membrane Bioreactor (Mbr)

MBR-Membrane Bioreactor is the combination of a membrane process like microfiltration or ultrafiltration with a biological wastewater treatment process, the activated sludge process.

RAW WATER TREATMENTS

Water treatment removes contaminants and undesirable components, reduces their concentration making it desirable. This treatment is essential to human health and allows humans to benefit from both drinking and irrigation use.

The raw water characteristics are checked and every single water quality problem is identified. Water treatment systems should be taken into account of the most practical and effective device to treat each concerning issues.

Process

Common Water Treatment Devices

-

Pressure Sand Filter

-

Activated Carbon filter

-

Iron Removal filter

-

Softener

-

Bag Filter

-

Micron Filter

-

Disinfection

-

1. Ultraviolent

-

2. Ozonation

-

3. Chlorination

-

Ultrafiltration

-

Reverse Osmosis

Primary Use

-

Removes Turbidity & Suspended Solids

-

Removes chlorine, organic, taste and odour Reduces BoD , CoD & TSS

-

Removes Suspended Iron

-

Removes Hardness

-

Reduce particles in large volumes of water at a high flow rate

-

Remove dirt, and even microscopic particles

-

The removal, deactivation or killing of pathogenic microorganisms

-

Destroys the DNA of microorganisms which leaves them dead and unable to grow further

-

Degradation of organic and inorganic pollutants

-

Kill parasites, bacteria, and viruses

-

Suspended particulate material to <1PPM of Bacterial and other Micro Organisms

-

Removes Salts & Micro Organisms

Complete Water Management With Zero Liquid

Reverse Osmosis

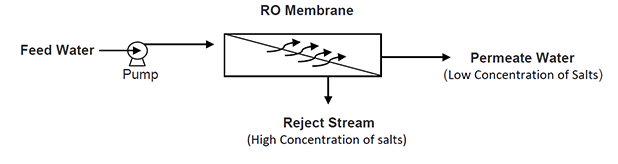

Reverse Osmosis, commonly referred as RO, is a process where water is demineralised by flowing under pressure through a semipermeable membrane. Osmosis is a naturally occurring phenomenon in which a weaker saline solution will tend to migrate to a strong saline solution.

A semi-permeable membrane is placed between 2 compartments. Semi-permeable means that the membrane is permeable to some species and not permeable to others. In this case, the membrane is permeable to water molecules but not permeable to dissolved ions and other contaminants.

In order to reach the equilibrium the water will pass from the pure water compartment to the salt-containing compartment, to dilute the salt solution.The equilibrium point of this water column height in terms of water pressure against the membrane is called osmotic pressure.

Working Principle

As the feed water enters the RO membrane under pressure (enough to overcome osmotic pressure), the water molecules pass through a semi-permeable membrane and the salts and other contaminants are not allowed to pass and are discharged through the concentrate stream, which goes to drain or can be fed back (totally or partially) into the feed water stream to be recycled through the RO system to save water or to solve hydraulic issues in the system.

Purpose Of RO

Any contaminant that has a greater molecular weight and ionic charge is most likely rejected by a properly running RO system. RO membranes do not remove gases like CO2 or O2. These gases are not highly ionized (charged) while they’re in solution and have a very low molecular weight.

- Municipal drinking water

- Food and beverage industry

- Agricultural irrigation

- Industrial ultrapure water

- Industrial process water

- Waste water reuse

- Power industry (boiler feed water, cooling towers)

- Municipal/industrial water reuse

- Households

Multiple Effect Evaporators

All evaporators are composed of two sections: a heating section (called a steam chest) and a vapor/liquid separation section. These sections can be located within a single vessel (body), or the heating section may be external to the vessel that houses the vapor/liquid separation section. In a multiple-effect evaporator, vapor from one body heats a second body at a lower boiling temperature. The first effect is heated directly with steam, and the additional bodies are ordered based on descending boiling temperature (or pressure).

Enquiry Form

Please fill out the form below and allow 48 business hours for our reply. We look forward to responding to your query.